PFAFF 3704

This highly specialized workplace is used for suit jackets and blazers. When manufacturing jackets, an even collar design is an indispensable quality feature. The PFAFF 3704 features special attachments (differential bottom feed and presser foot with thread-drawing finger) that enable an exact distribution of the fullness and, after a short operator training ensure an optimum and uniform collar shape. The PFAFF 3704 is available in two versions (-2/02 and -2/03) that match the two most frequently used processing methods.

Features

- Application of fullness with the differential bottom feed and compensating presser with guide improves handling

- Very light and soft sewing, even on very thin fabrics

- Consistently uniform collar shape as the undercollar felt is not pulled out of shape while fullness is being applied into the top collar

- Consistent sewing of undercollars on top collars is ensured

- Imitated hand-sewn effect (tailored look) after the collar is turned

- Performance: Effective output of approx. 500 - 600 jacket collars in 8 hours

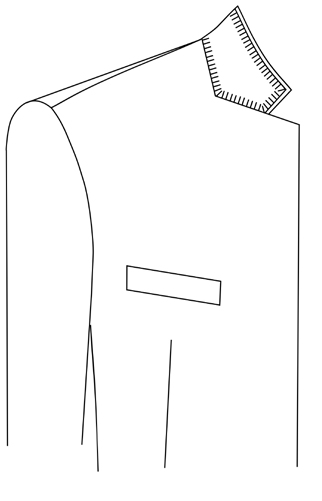

Work method of the PFAFF 3704-2/02

Sewing start with automatically condensed stitches and activated differential bottom feed up to the corner of the collar with application of the fullness in the underlying top collar. After the needle has been positioned in the corner of the collar, turn the workpiece by 90 degrees and sew the long side up to the second collar corner. Here, too, the fullness is applied to the underlying top collar where required.

After the needle has been positioned in the second collar corner, turn the workpiece by 90 degrees and sew the last section. With the reverse pedal function, the automatic stitch condensation, thread trimming and automatic foot lift functions are triggered. The automatic thread puller guarantees a reliable seam start in the next part even with the largest zigzag stitch set.

Result: The thread drawing finger, which is attached to the sewing foot, ensures a loose stitch formation and achieves an imitated hand-sewn effect when the collar is turned.

Features of the PFAFF 3704-2/02

- Consistent sewing of undercollars and top collars due to a special edge guide

- Imitated hand-sewn effect on the edge of the collar after the collar is turned (tailored look)

- Soft collar processing, a big advantage when sewing thin materials

- Efficient processing method with low demands on the operator

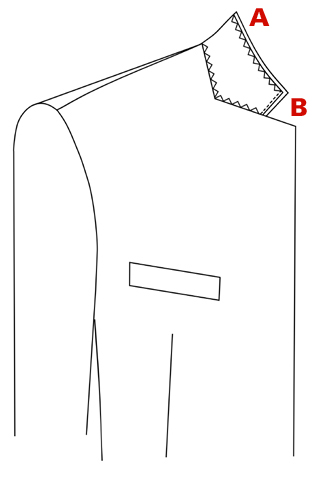

Work method of the PFAFF 3704-2/03

Attaching undercollar to top-collar with differential bottom feed. The fullness is sewn into the right section of the topcollar which is lying underneath.

(A) Edge of top-collar is sewn with straigtht stitch into the felt with 1mm edge margin. (B) Result: The sewing fittings used here result in a visible zigzag seam when the collar is turned and a seamless bottom collar edge is visible

Features of the PFAFF 3704-2/03

- Consistently uniform collar shape as the undercollar felt is not pulled out of shape while fullness is being applied into the top collar

- Consistent sewing of undercollars and top collars due to a special edge guide

- Efficient processing method with low demands on the operator

Applications

Sewing undercollar to top collar

Specifications

Needle system: 134 EL

Needle size: 80 - 100 Nm

Max. sewing speeds: 5.000 s.p.m

Max. stitch length: Basic stitch length 2,5 mm, Gathering stitch length 4,5 mm

Max. zigzag stitch width: max. 6,0 mm

Stitch type: 304 (Zigzag-Lockstitch)

Fabric clearance: max. 7,0 mm

Clear workspace: 260 x 130 mm

Connection voltage: single-phase a.c. 230 V, 50/60 Hz

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!