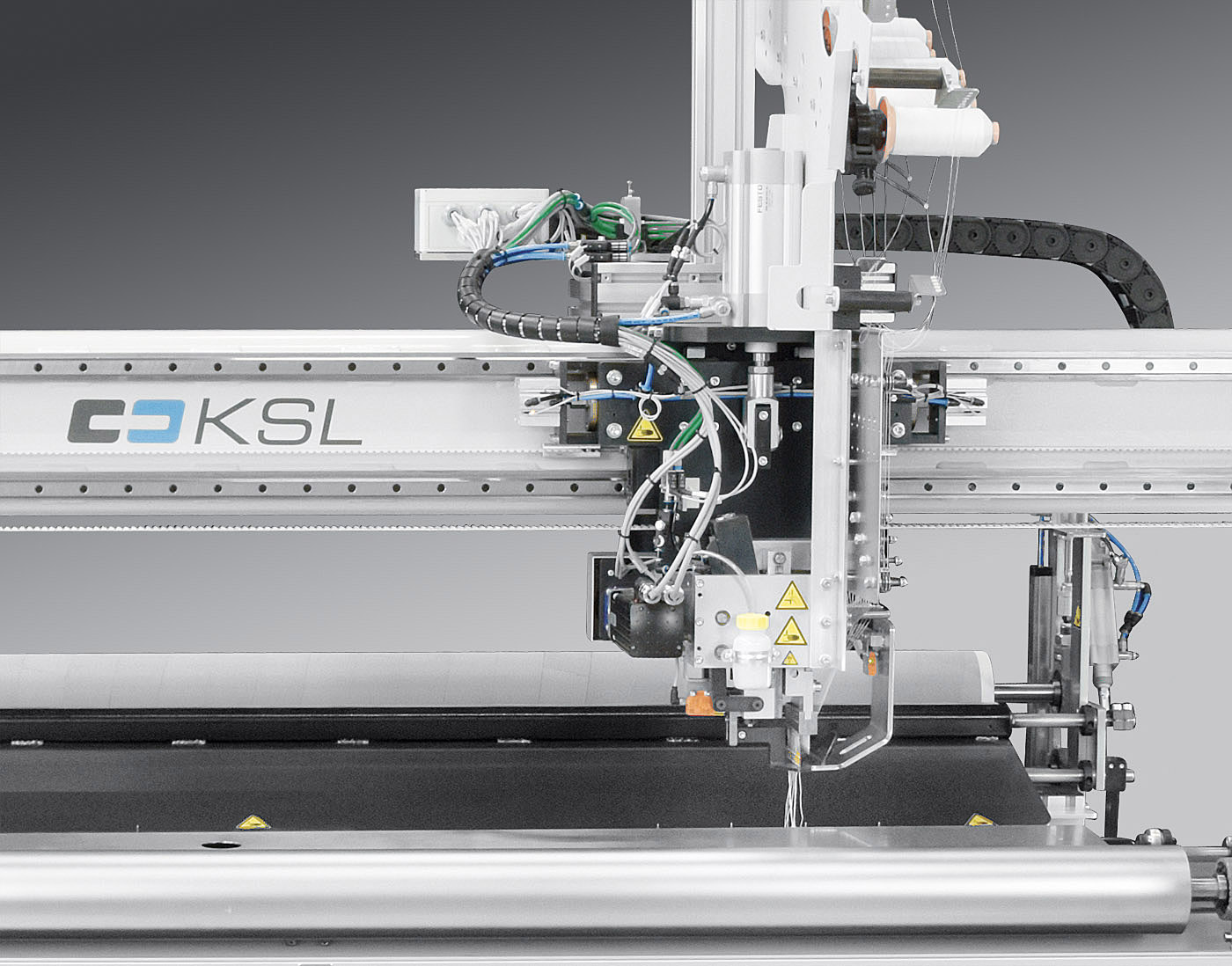

KL 220

10-needle sewing unit for sewing straight seams

Features

- Sturdy steel portal for take-up of the cross sewing head

- Linear guiding system with tooth belt drive for cross travel of the mechanically divided cross sewing head

- Less product waste (on both ends of the role), because the machine can be integrated into the material flow

- Min. material width: 600 mm, max. material width: 2,000 mm (up to 3,600 mm on request)

- Pneumatic presser foot lift (automatically)

- Thread withdrawal device for tension free and twist-free withdrawal of the sewing threads

- Tension- and puckering free processing of polyamide, polyester and viscose fabric

- Materials are stacked in min. 2 layers

- Separating unit for chain threads (hot cutting unit)

- Liftable material clamping at the right of the cross sewing head to fix the material during the sewing process

- Stationary needle holders, left and right of the sewing head, to stretch and fix the material

- Lifting unit to lift the material out of both needle holders

- Photocell monitoring for recognition of the beginning and the end of the material

- New: Integrated security system

Specifications

Max. sewing speed: 1.000 s.p.m.

Max. stitch length: 12 mm

Needle gauge: 9 mm (10 needles)

Max. needle size: 180 Nm

PFAFF Industrial at Facebook

PFAFF Industrial at Youtube

PFAFF Industrial at LinkedIn

PFAFF Industrial at Instagram

News as RSS Feeds

This site is mobile!